Armstrong

Introduction

Armstrong Logistics, a leading provider of supply chain solutions, recognized the need to modernize its cleaning processes for its fleet of vehicles. Previously reliant on manual cleaning methods, the company sought to enhance efficiency and effectiveness through automation. After a thorough evaluation of the vehicle wash industry, Armstrong Logistics chose Brendeck as its partner for the new Truck Wash Facility. This case study explores the decision-making process, the collaboration between the two companies, and the impact of the new automated system, with a focus on sustainability and efficiency.

Challenges Faced

Before partnering with Brendeck, Armstrong Logistics faced several challenges with its manual cleaning approach:

- Inefficiency: Manual washing was time-consuming, leading to delays in vehicle readiness.

- Inconsistent Quality: Variability in cleaning quality often resulted in suboptimal results.

- Labour-Intensive: The reliance on manual labour created operational bottlenecks and increased labour costs.

- Environmental Concerns: Armstrong was also looking to enhance sustainability in their operations.

The Need for Automation and Sustainability

To address these challenges, Armstrong Logistics sought an automated solution that could streamline the washing process, reduce labour costs, and ensure consistent quality. Additionally, the company prioritized sustainable practices, aiming to minimize water usage and environmental impact.

Selection of Brendeck

Armstrong Logistics conducted extensive research into various vehicle wash providers. After reaching out to multiple companies, it became clear that Brendeck stood out in several key areas:

- Customer-Centric Approach: Armstrong Logistics noted that Brendeck was "by far the most helpful" during the initial discussions, demonstrating a genuine interest in understanding their needs.

- Professionalism: Throughout the selection process, Brendeck’s team displayed exceptional professionalism and expertise.

- Collaborative Spirit: Armstrong appreciated Brendeck's willingness to work as a team, ensuring that all concerns were addressed and solutions tailored to their specific requirements.

Decision to Partner

Ultimately, Armstrong Logistics decided to move forward with Brendeck based on their positive interactions, innovative solutions, and shared commitment to sustainability.

Project Implementation

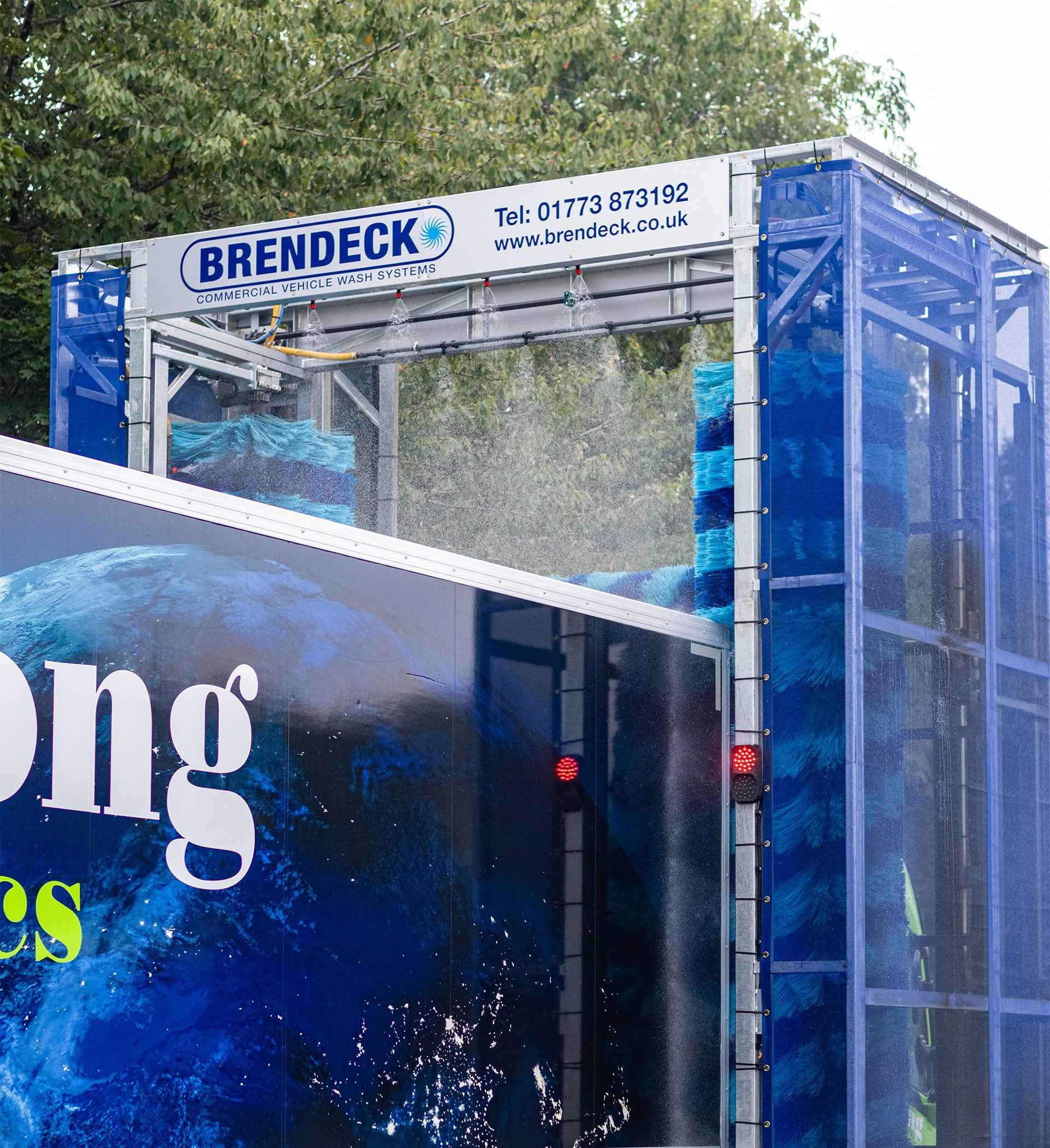

From the outset, the partnership between Armstrong Logistics and Brendeck was marked by strong collaboration. Brendeck’s team worked closely with Armstrong to design a Truck Wash Facility that would meet their operational needs while incorporating the latest technology and sustainable practices.

- Water Recycling System: A key feature of the new wash facility is Brendeck's innovative water recycling system, which captures and recycles 90% of the water used during the cleaning process. This not only saves money but significantly improves sustainability by reducing water consumption.

- Advanced Cleaning Technology: The Brendeck 3-brush rollover system is programmed for a double pass operation, ensuring thorough cleaning within just 7 minutes. This efficiency allows Armstrong to maximize vehicle availability without compromising on quality.

- Tailored Solutions: Brendeck provided customized solutions, ensuring the wash system was optimized for the specific types of vehicles in Armstrong’s fleet.

- Timely Delivery: The project was completed on schedule, demonstrating Brendeck's commitment to meeting deadlines and maintaining clear communication throughout the process.

Impact of the New Truck Wash Facility

Now that the project is complete, Armstrong Logistics has experienced significant benefits from the new automated wash system:

- Increased Efficiency: The new system dramatically reduces the time required for vehicle cleaning, allowing for quicker turnaround times and increased vehicle availability.

- Consistent Quality: The automated wash process ensures a uniform cleaning standard across the fleet, enhancing the overall appearance and maintenance of vehicles.

- Sustainability Achieved: With the water recycling system in place, Armstrong has significantly reduced its environmental impact while saving on operational costs.

- Modernized Operations: Armstrong Logistics has successfully brought its cleaning process into the 21st century, aligning with their broader goals of operational modernization and sustainability.

Feedback from Armstrong Logistics

In their own words, Armstrong Logistics commended Brendeck by stating, "Brendeck was brilliant to work with from start to finish. They were professional and worked well as a team. The efficiency of our new automatic wash has transformed our cleaning process, and the sustainable solutions have been a game changer for us."

Conclusion

The partnership between Armstrong Logistics and Brendeck exemplifies the benefits of embracing innovation and automation in logistics operations. By transitioning from manual cleaning to an automated system, Armstrong has significantly improved operational efficiency, quality, and sustainability. This successful collaboration not only modernized their truck wash facility but also set a benchmark for future projects in the industry. Armstrong Logistics looks forward to a continued partnership with Brendeck as they further enhance their operations.